PLG Supplies: Complete Guide for Businesses and Product-Led Growth

PLG supplies are essential tools, resources, and operational materials that help businesses implement effective product-led growth strategies. These supplies include industrial tools, office essentials, safety gear, packaging materials, and workflow systems that streamline operations, improve productivity, and enhance user experiences. Businesses rely on PLG supplies to support both digital and physical product workflows.

By choosing the right PLG tools and resources, companies can optimize efficiency, maintain compliance, and scale their operations seamlessly. From managing industrial equipment to organizing office workflows, these supplies play a critical role in enabling teams to execute product-led growth strategies, improve activation rates, and deliver a better overall customer experience.

What Are PLG Supplies?

PLG supplies refer to the essential tools, resources, and processes that help businesses adopt a product-led growth strategy. These supplies can include everything from onboarding tools to analytics, automation systems, customer insights platforms, and internal workflow frameworks. Companies use these resources to improve product experience and drive growth directly from the product itself.

In simple terms, PLG supplies act as the building blocks that support PLG workflows, helping teams understand user behavior, increase activation rates, and optimize customer journeys. Whether you’re a startup or an established company transitioning to a product-led strategy, these supplies help streamline operations and enhance decision-making.

As more companies shift toward self-serve models, PLG tools and resources are becoming essential for achieving sustainable growth. They help teams deliver faster outcomes, reduce dependency on sales-led funnels, and create a seamless product experience that naturally drives conversions.

Types of PLG Supplies (Full Breakdown)

Understanding the different types of PLG supplies helps businesses choose the right tools and resources to support product-led workflows. Each category offers specific benefits that improve productivity, customer experience, and operational efficiency. Below is a complete breakdown of the most important supply types used in PLG-focused environments.

1. Industrial & Maintenance Supplies

Industrial and maintenance PLG supplies include essential tools used to keep operations running smoothly. These resources support product teams, warehouse operations, and technical workflows. Items in this category often include equipment repair tools, maintenance kits, hardware accessories, and machine-safety components.

For companies following a product-led growth strategy, reliable industrial supplies help maintain consistent product performance. They are especially useful for teams handling physical products, prototypes, and testing environments. By incorporating the right industrial tools, companies improve product reliability and ensure their PLG workflows never stall due to equipment issues.

2. Safety & PPE Supplies

Safety and PPE supplies protect employees during product handling, warehouse management, or technical operations. These PLG supplies are essential for companies managing manufacturing processes, on-site testing, or hands-on product work. Common items include gloves, eyewear, helmets, respiratory masks, and workplace safety equipment.

In PLG-oriented companies, strong safety workflows ensure the product team stays protected while working on product features or physical assets. These supplies also improve compliance standards, reduce downtime, and support efficient product-led growth operations.

3. Janitorial & Facility Supplies

Janitorial and facility supplies help maintain a clean, orderly, and productive work environment. They include cleaning tools, sanitization products, waste bags, restroom supplies, floor care equipment, and general facility maintenance items.

Clean and well-maintained facilities support smoother PLG operations by eliminating distractions, reducing workplace hazards, and keeping teams focused. When teams operate in a structured and hygienic environment, product-led workflows become more efficient, improving overall output and decision-making.

4. Packaging & Storage Supplies

Packaging and storage supplies are critical for managing inventory, shipping products, and organizing workspace materials. This category includes boxes, tapes, storage bins, labels, containers, pallets, and protective packaging materials.

Packaging is especially important for companies offering PLG-driven physical products since it directly affects the customer experience. Proper storage supplies also support internal workflows by keeping tools and PLG resources organized and accessible. With better organization comes faster execution, fewer errors, and smoother product-led operations.

Why PLG Supplies Matter for Modern Businesses

Understanding the value of PLG supplies is essential for any company shifting toward a product-led growth strategy. These tools and resources are not just add-ons, they form the backbone of how teams operate, optimize workflows, and scale efficiently.

1. Supporting Product-Led Workflows

PLG supplies make it easier for teams to manage product data, user insights, onboarding journeys, and internal operations. Whether it’s analytics platforms or physical supplies like packaging and storage, each one contributes to a smoother workflow. With better PLG tools, companies can reduce friction, improve product usability, and boost customer satisfaction.

2. Enhancing User Experience & Activation

One of the biggest goals of any product-led company is to improve user activation. PLG supplies, from digital resources to operational tools, help create experiences that guide users naturally toward value. This leads to higher retention, fewer support requests, and stronger product adoption without relying heavily on sales teams.

3. Streamlining Internal Operations

A well-organized workplace supported by the right supplies improves productivity. Clean facilities, strong safety workflows, and proper packaging materials reduce delays and allow product teams to focus on building and improving the product. This operational efficiency directly supports long-term product-led growth.

4. Reducing Costs With Self-Serve Systems

PLG strategies often rely on self-serve systems, which naturally reduce operating and support costs. The right PLG supplies enable better automation, clearer data, and smoother onboarding journeys. When customers can find value on their own, businesses spend less on manual support and more on improving the product.

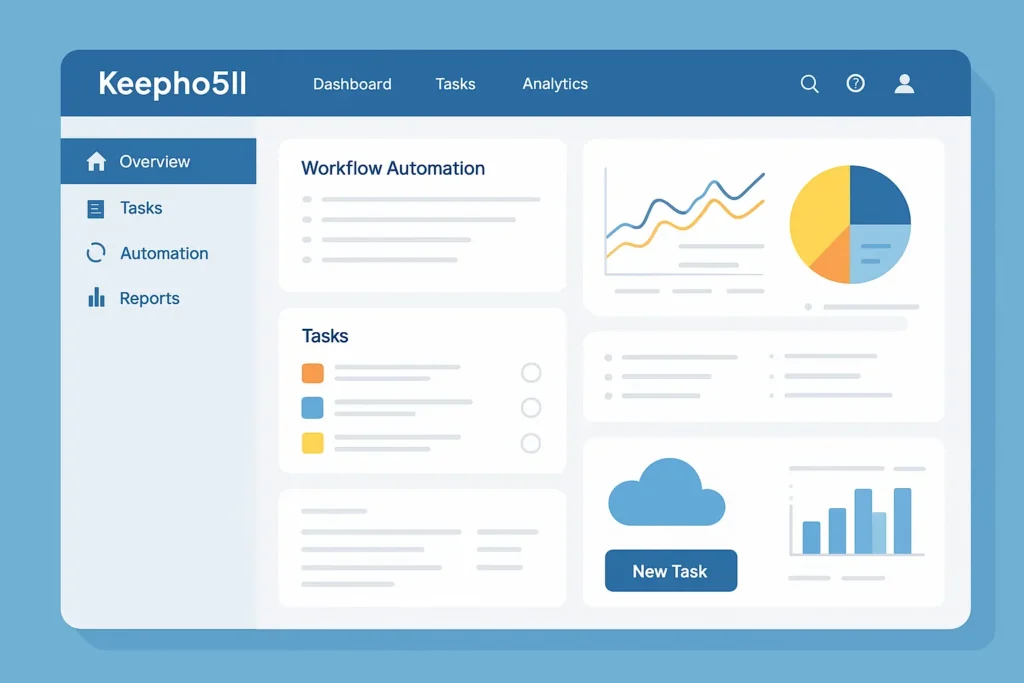

How PLG Supplies Improve Workflow Efficiency

PLG supplies help teams streamline daily operations by providing the right tools, resources, and systems needed for smooth product-led workflows. From analytics platforms to packaging and facility materials, these supplies reduce friction and create consistent processes. This improved structure allows teams to focus more on product performance, user experience, and growth-driven decisions.

Using optimized PLG supplies also improves internal collaboration by keeping work environments organized, clean, and safe. With proper storage, maintenance, and PPE supplies, teams can operate confidently and efficiently. These resources support faster execution, reduce downtime, and ensure every part of the product-led growth system functions reliably across departments.

Workflow efficiency increases when companies integrate the right industrial, janitorial, and operational PLG tools into their processes. These supplies help maintain product quality, enhance user activation, and support a self-serve growth model. As teams gain easy access to essential PLG resources, they deliver better results while maintaining a scalable product-led growth structure.

Pricing Models for PLG Supplies

Understanding pricing models for PLG supplies helps businesses make informed decisions when procuring essential tools, resources, and operational materials. Choosing the right pricing model ensures cost efficiency, consistent supply, and scalability for product-led growth workflows. Below is a detailed overview of the most common pricing approaches used by companies.

1. Wholesale vs Retail Pricing

Wholesale pricing is ideal for businesses looking to buy large quantities of PLG supplies at a lower per-unit cost. It benefits organizations managing industrial tools, packaging, and maintenance products. Retail pricing, on the other hand, suits small businesses or teams requiring limited quantities of office supplies, safety gear, or janitorial products.

Wholesale pricing encourages bulk purchasing and long-term partnerships, while retail pricing offers flexibility and accessibility for smaller or urgent orders. By understanding the difference, companies can balance cost and convenience to support both operational efficiency and product-led growth strategies.

2. Bulk Procurement Pricing

Bulk procurement pricing focuses on offering discounts for large volume orders of PLG supplies, including industrial equipment, PPE, office essentials, and storage materials. This model benefits businesses that require consistent, high-volume shipments to maintain smooth workflows.

Using bulk procurement not only reduces costs but also ensures a steady supply of essential resources. Companies can plan long-term operations, optimize inventory management, and strengthen product-led workflows by having the right supplies on hand without frequent reordering delays.

3. Long-Term Supplier Contracts

Long-term supplier contracts provide businesses with guaranteed pricing, consistent delivery schedules, and prioritized service for PLG supplies. These contracts are especially useful for industrial tools, packaging materials, and recurring safety supplies that are critical for product-led growth operations.

By establishing long-term agreements, companies can lock in favorable pricing, reduce procurement risks, and maintain a reliable supply chain. This approach supports strategic planning, workflow efficiency, and continuous access to high-quality resources that sustain growth initiatives.

4. Subscription / Recurrent Supply Models

Subscription or recurrent supply models allow businesses to automate regular deliveries of PLG supplies, from office stationery to PPE and janitorial materials. This pricing model supports product-led growth by reducing administrative burden, preventing stockouts, and ensuring teams always have essential tools available.

Recurrent supply models improve operational predictability and workflow continuity. Businesses can focus on enhancing product experiences rather than managing frequent procurement tasks, making this model ideal for companies aiming to scale efficiently while maintaining a streamlined supply system.

How to Choose the Best PLG Supplies for Your Needs

Choosing the right PLG supplies is essential for businesses looking to optimize product-led workflows and achieve sustainable growth. Start by evaluating your operational needs, considering which tools and resources will have the most impact on efficiency, safety, and overall productivity. Industrial tools, office essentials, PPE, packaging, and facility materials all play a role in maintaining smooth processes.

Next, compare suppliers based on product quality, reliability, and pricing models. Whether you prefer wholesale, bulk procurement, long-term contracts, or subscription-based supply models, selecting a supplier that meets your business requirements ensures consistent access to essential resources. This reduces downtime, supports compliance, and strengthens product-led growth initiatives across departments.

Finally, consider eco-friendly and sustainable options when choosing PLG supplies. Materials that are durable, energy-efficient, or recyclable not only support workplace safety and efficiency but also reflect positively on your company’s commitment to sustainability. By carefully selecting PLG supplies tailored to your operations, you create a streamlined, scalable, and productive environment that reinforces your product-led growth strategy.

Mistakes Businesses Make When Buying PLG Supplies

Many businesses struggle to get the most value from their PLG supplies because of common mistakes that hinder efficiency and growth. One frequent error is focusing solely on price rather than quality. Choosing cheaper industrial tools, office essentials, or safety gear can lead to frequent replacements, workflow disruptions, and reduced productivity.

Another mistake is neglecting supplier reliability and delivery timelines. Inconsistent supply chains or late shipments of packaging materials, janitorial products, or PPE can slow down product-led workflows and increase operational costs. Companies that fail to establish strong supplier relationships often face repeated stockouts and process interruptions.

Lastly, businesses sometimes overlook the importance of matching supplies to specific operational needs. Buying generic or mismatched PLG tools and resources can result in cluttered workspaces, wasted materials, and lower efficiency. Understanding the exact requirements of industrial, office, and facility operations ensures that each PLG supply supports seamless workflows and contributes to sustainable growth.

The Role of PLG Supplies in Workplace Compliance & Safety

PLG supplies play a critical role in maintaining workplace safety and regulatory compliance. From PPE and industrial tools to janitorial and facility supplies, having the right resources ensures employees can work safely while supporting product-led workflows. Proper safety gear reduces accidents, protects staff, and minimizes disruptions in operations.

Compliance with industry standards, such as OSHA, ANSI, or ISO regulations, often depends on the availability of appropriate PLG supplies. Companies that provide the correct tools, safety equipment, and facility resources demonstrate a commitment to regulatory adherence while also improving workflow efficiency. This dual benefit strengthens both internal operations and external credibility.

Using the right PLG supplies also helps businesses create a culture of safety and responsibility. When teams have access to reliable tools, organized storage, and effective sanitation resources, they are empowered to focus on productivity, quality, and growth. This approach reduces risks, fosters trust, and ensures that product-led strategies can scale successfully.

Sustainability in PLG Supplies

Sustainability in PLG supplies is becoming increasingly important for businesses aiming to reduce environmental impact while maintaining efficient workflows. Eco-friendly office materials, energy-efficient industrial tools, biodegradable cleaning products, and recyclable packaging not only support environmental responsibility but also enhance operational efficiency and product-led growth initiatives.

Choosing sustainable PLG supplies helps companies reduce waste, lower costs, and improve brand reputation. By prioritizing durable, reusable, and environmentally conscious resources, businesses can maintain smooth industrial, office, and facility operations without compromising on performance or safety. These supplies align with modern compliance standards and demonstrate a commitment to long-term sustainability.

Integrating sustainability into PLG workflows also encourages teams to adopt more responsible practices in day-to-day operations. From managing packaging materials to using energy-efficient tools and PPE, businesses can create a culture of environmental awareness that supports both growth and efficiency. This approach ensures PLG strategies remain scalable, compliant, and future-ready.

How to Evaluate PLG Suppliers

Evaluating the right PLG suppliers is essential for ensuring consistent access to high-quality tools, industrial equipment, office essentials, and facility resources. Reliable suppliers help maintain smooth product-led workflows by providing timely delivery, durable products, and responsive customer support, all of which are critical for operational efficiency and growth.

When assessing suppliers, consider product quality, pricing models, and supply chain reliability. Whether opting for wholesale, bulk procurement, long-term contracts, or subscription-based supply models, businesses need vendors that can meet their volume requirements and maintain consistent stock. This ensures that PLG workflows remain uninterrupted and scalable.

Additionally, supplier evaluation should include certifications, compliance standards, and after-sales support. A trustworthy PLG supplier provides resources that adhere to industry regulations, maintains safety standards, and helps businesses integrate sustainable and efficient supplies into their operations. Choosing the right supplier strengthens both workflow efficiency and product-led growth initiatives.

Best Practices for Managing PLG Supplies

Effectively managing PLG supplies is key to maintaining smooth workflows and supporting product-led growth strategies. Businesses should implement organized storage systems, track inventory levels, and monitor usage patterns for industrial tools, office essentials, PPE, and janitorial supplies. Proper management ensures resources are always available when needed.

Regular audits and inventory checks help prevent overstocking or stockouts, reducing waste and operational delays. Integrating technology such as inventory management software or automated replenishment systems allows teams to streamline PLG workflows, ensuring all supplies are optimized for efficiency and reliability.

Training employees on proper handling and storage of PLG supplies also boosts productivity and prolongs the lifespan of equipment and materials. By following these best practices, companies can maintain organized, cost-effective, and scalable operations that reinforce both workplace efficiency and product-led growth.

Future Trends in PLG Supplies Industry

The PLG supplies industry is evolving rapidly as businesses adopt more product-led growth strategies. Emerging trends include AI-powered inventory management, smart industrial tools, and automated supply replenishment systems. These innovations help companies streamline workflows, reduce operational delays, and maintain consistent access to essential resources.

Sustainability is another growing focus, with eco-friendly office materials, biodegradable packaging, and energy-efficient tools gaining popularity. Businesses that adopt these sustainable PLG supplies not only reduce environmental impact but also enhance brand reputation, operational efficiency, and long-term cost savings.

Finally, global supply chain improvements and digital procurement platforms are shaping the future of PLG supplies. Companies can access a broader range of vendors, compare pricing models, and implement subscription or bulk procurement strategies more effectively. Staying ahead of these trends ensures businesses maintain scalable, efficient, and future-ready product-led workflows.

Conclusion

Choosing and managing the right PLG supplies is essential for businesses aiming to implement effective product-led growth strategies. From industrial tools and office essentials to safety gear and packaging materials, every resource plays a role in supporting workflows, enhancing productivity, and ensuring operational efficiency.

By selecting reliable suppliers, optimizing inventory management, and adopting sustainable practices, companies can reduce costs, maintain compliance, and scale their operations with confidence. Proper PLG supplies not only improve internal workflows but also enhance customer experience and product adoption, which are critical for long-term growth.

Investing in the right PLG tools, resources, and systems ensures businesses are well-prepared to meet evolving market demands. By integrating these supplies into daily operations, companies can create a streamlined, scalable, and efficient environment that supports continuous innovation and drives successful product-led growth outcomes.